Tianjin yuantaiderun group JCOE Φ 1420 large straight seam unit put into operation to fill the gap in Tianjin market

Tianjin yuantaiderun group JCOE Φ 1420 large straight seam unit put into operation to fill the gap in Tianjin market

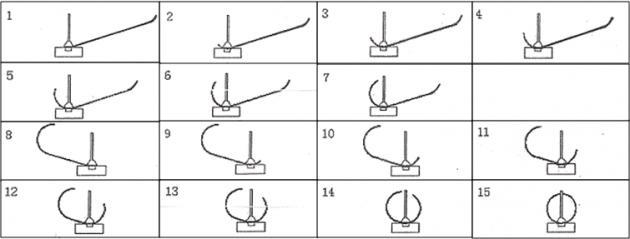

JCOE is a pipe making technology for producing large-diameter thick wall steel pipe. It mainly adopts the production process of double-sided submerged arc welding. The products go through multiple processes such as edge milling, pre bending, bending, joint, internal welding, external welding, straightening, flat head and so on. The forming process can be divided into N + 1 steps (n is a positive integer). The steel plate is automatically fed horizontally and bent according to the set step, so as to realize NC progressive j-c-o forming. The steel plate enters the forming machine laterally, and under the push of the feeding trolley, the multi-step successive bending of N / 2 steps in the first stage is carried out to realize the "J" forming of the front half of the steel plate; In the second stage, firstly, the steel plate formed by "J" is quickly fed laterally to the specified transverse position, and the unformed steel plate is subjected to another n / 2 step multi-step successive bending from the other end to realize the forming of the second half of the steel plate and complete "C" forming; Finally, the lower part of "C" tube blank is bent once to realize "O" forming. Each stamping step takes three-point bending as the basic principle.

JCOE steel pipe plays an important role in large-scale pipeline engineering, water and gas transmission engineering, urban pipe network construction, bridge piling, municipal construction and urban construction. In recent years, as a new energy-saving and environmental protection building system, steel structure building is known as the "green building" in the 21st century. In more and more high-rise and super high-rise building design schemes, steel structure or steel-concrete structure system is preferred, and space grid structure, three-dimensional truss structure, cable membrane structure and prestressed structure system are actively adopted for long-span buildings, which enable steel pipes to obtain more application scenarios in construction engineering The demand for super thick wall steel pipes has also increased significantly.

JCOE steel pipe plays an important role in large-scale pipeline engineering, water and gas transmission engineering, urban pipe network construction, bridge piling, municipal construction and urban construction. In recent years, as a new energy-saving and environmental protection building system, steel structure building is known as the "green building" in the 21st century. In more and more high-rise and super high-rise building design schemes, steel structure or steel-concrete structure system is preferred, and space grid structure, three-dimensional truss structure, cable membrane structure and prestressed structure system are actively adopted for long-span buildings, which enable steel pipes to obtain more application scenarios in construction engineering The demand for super thick wall steel pipes has also increased significantly.

The "round to square" unit independently developed by Tianjin yuantaiderun group has a maximum processing diameter of 1000mm × 1000mm square pipe, 800mm × 1200mm rectangular tube, processing capacity of super large diameter and super thick wall rectangular tube with maximum wall thickness of 50mm, has successfully supplied up to 900mm for the domestic market × 900mm × 46mm, outlet up to 800mm × 800mm × 36mm super large diameter and super thick wall products meet a variety of complex technical requirements of users at home and abroad, including 400mm rectangular tube × 900mm × 30mm products also represent the leading level of "round to square" process at home and abroad.

Wuhan Greenland center, the third tallest building in the world - the super high-rise landmark skyscraper in Wuhan, China with a design height of 636m, is a representative super high-rise steel structure project supplied and serviced by Tianjin yuantaiderun group.